Urban rail and subway

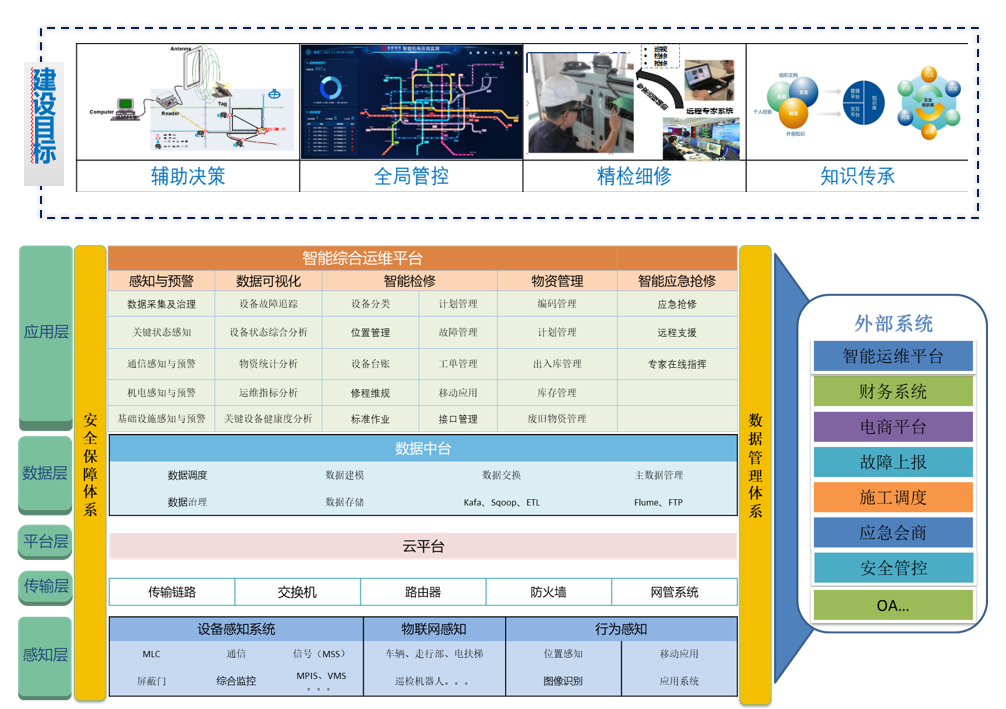

The Intelligent Maintenance Platform (IMP) is a specialized software solution based on the ISO55000 asset management system, designed for intelligent maintenance and support of equipment in the railway industry. The platform comprises six software systems: intelligent perception, material procurement, physical assets, intelligent equipment maintenance, intelligent statistical analysis, and maintenance knowledge base, along with an operation and maintenance middle platform. The platform addresses key challenges in asset and equipment operation and maintenance within the transportation industry. It caters to management and control needs, enhances ease of use for operational tasks, facilitates intelligent equipment perception, and enables predictive maintenance. It also supports comprehensive management of the repair process, standard operations, and maintenance work orders through digitization means, achieving standardization and intelligence in management and maintenance.

The platform provides global control over the operational status of IT, Internet of Things (IoT), and other infrastructure. It standardizes operation and maintenance processes and digitizes repair procedures. On-site maintenance is streamlined and mobile, ensuring the normal operation of resources in real time.

The platform interlocks the operation data of the equipment to enable real-time sensing of operation status. It models the health of critical intelligent equipment, including professional traction, braking systems, traveling parts, signal turnouts, and escalators. The system predicts, issues warnings, and performs repairs based on equipment health, and connects with emergency repair protocols, material inventory, and maintenance strategies in real-time. This approach enhances the efficiency of equipment operation and maintenance.

The rail traffic intelligent operation and maintenance platform uses digital technologies to monitor equipment operation status in real time. It detects anomalies, provides timely warnings, and ensures the safe operation of the equipment.

The platform has established an industry standard system that includes standards for data collection, maintenance systems, material management, index systems, and knowledge bases.

By accumulating knowledge from fault handling, operation and maintenance experiences, and expert insights, the platform builds a knowledge base that facilitates knowledge transfer and inheritance.

The platform has established intelligent models for vehicle traction, braking systems, and signal-base turnout junctions, assisting rail traffic companies in enhancing operational efficiency and safety.

The platform has established three core applications: intelligent maintenance, material management and control, and decision analysis. These applications enable global management and control of rail operations, precise maintenance, and efficient decision-making.

Scenario 1: Rail traffic operation monitoring

The platform collects key state data from infrastructure, electromechanical equipment, and communication systems to track equipment faults, perform comprehensive status and health analysis, and conduct statistical and operational maintenance metrics analysis of materials.

Scenario 2: Fine maintenance for rail equipment

The platform achieves precise equipment positioning and accurate failure prediction analysis by integrating equipment status, location data, and digital twinning technology. The platform achieves precise equipment inspection and maintenance through standardized operations, reducing manual troubleshooting workload and improving maintenance efficiency.

Tianjin Metro Vehicle and Facilities Intelligent Operation and Maintenance Platform

A Metro Operation Group OMC Phase I and Phase II