Customer: Jincheng Thermal Power Co., Ltd.

Industry: Thermal Industry

Products/Solutions: Long-distance Transmission Control System Based on Metarge Platform

Keywords: Long-distance Pipeline, Business Integration, Data Integration

As urban construction rapidly develops and centralized heating coverage expands, urban heating sources are becoming increasingly scarce. In order to promote energy conservation, reduce energy consumption, and improve the urban environment, Jincheng has implemented the Yangcheng Power Plant to Jincheng District Centralized Heating Long-distance Transmission Project. It is a key project of the municipal government, affecting the heating scale of 30 million square meters. In order to meet the functional needs of large capacity, high concurrency, high stability and customized development of the Jincheng long-distance transportation project and the city's internal heat network project, Beiming Tianshi has deployed 2 sets of SCADA monitoring systems and adopted the idea of microservices to create the Metarge comprehensive management platform for the heat company's smart heat network. Through advanced digital technology, the platform provides refined monitoring, graded alarm and interlock protection mechanisms for the long-distance transmission process, helping thermal enterprises achieve comprehensive monitoring of long-distance transmission, and unified municipal heat network coordination. By building a shared data service system, it created an integrated application system based on a unified thermal map.

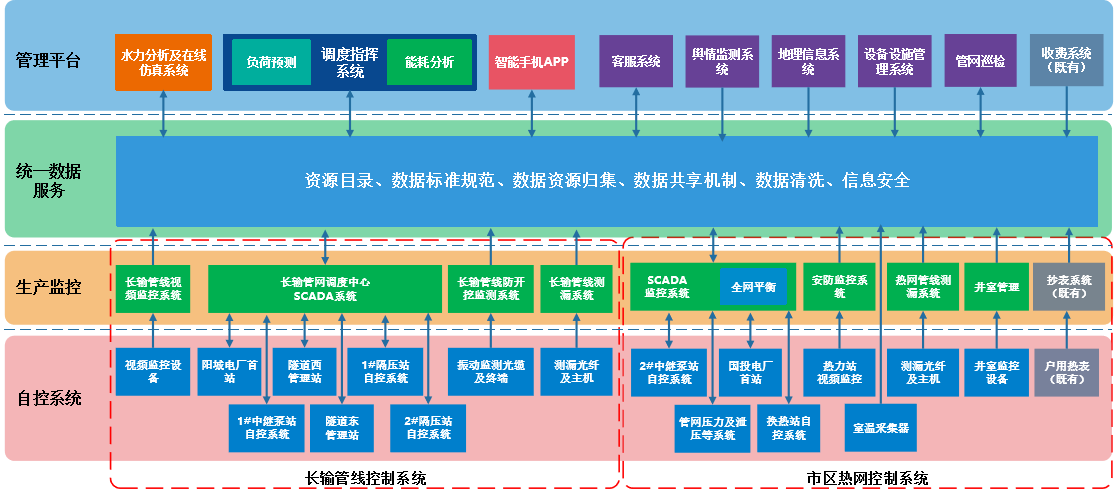

Analyzing the needs of thermal enterprises, Beiming Tianshi proposes an information service system framework of "one platform, two centers" based on the production and operation of thermal systems, providing thermal enterprises with an integrated management solution for "source, network, station and household". "One platform, two centers" refers to the construction of the unified intelligent heating service platform, Metarge. This involves integrating the production management system based on thermal production scheduling into the "Heat Network Production Dispatch Center". Simultaneously, the business management system, centered on operational and business management, is integrated into the "Heating Operation Management Center".

The construction of the intelligent heating supervision system is aimed at realizing the automation control of heating, and using the new generation of Internet of Things, cloud computing, intelligent algorithms and other technologies to upgrade the information technology of the whole process of the heating system from source, network, station, to the household. This upgrade allows the government to manage, enterprises to control, and residents to feel the improvements.

To ensure the continuous and stable operation of the long-distance transmission system, the system implements a complete monitoring, graded alarm and interlock protection mechanism for the processes. In the event of severe emergencies, the system can carry out necessary pre-treatment and interlocking actions before the monitoring personnel respond.

1. Multifunctional Application

In the long-distance transmission system, where there are many types of and complex equipment at stations, the Metarge Yuanhe Platform relies on the underlying SCADA system. Engineers can achieve custom drivers and data collection functions through secondary development. Alternatively, they can directly address various data collection issues using WebService or Socket, significantly reducing equipment costs and debugging time.

2. High Availability

The platform is based on API functions such as multi-thread support, thread management, and resource protection between threads, making it suitable for high IO and high-concurrency scenarios. Users with advanced language multi-threaded programming knowledge can easily achieve high-concurrency control logic by writing script code, reducing subsequent secondary debugging and development.

3. Openness and Efficiency

The long-distance transmission project is based on the openness of the Metarge platform, enabling efficient development. The platform makes extensive use of code to automatically build data models, and generate necessary functions such as driver acquisition, alarm configuration, and archiving, which improve system development and operation efficiency.

Yangcheng Power Plant to Jincheng District centralized heating network long-distance transmission project covers the construction of a dispatch center, redundant automated control system, and and system integration, collection, and control for the primary long-distance heat source station, pipeline monitoring, plant automatic control, emergency spill and drainage points, tunnels and more, collection and control.

The long-distance transmission control system ensures the systematization of the project in terms of communication information sharing, control logic coordination, coordination of general control and sub-control dispatch, supply and balancing supply across the network, etc., meeting the stable operation needs of the long-distance transmission project. The long-distance transmission dispatch center can carry out full-line data monitoring and remote unified control of the operating conditions, load regulation and emergency command of the entire long-distance transmission system. The control center of each pumping station and energy station can realize the monitoring and control of the automatic control system in the station through the local monitoring system. The control right of the system can realize a seamless switch between the two control centers. It effectively ensures the stable operation of the long-distance transmission system.

In the context of national efforts to enhance clean energy utilization and reduce carbon emissions, the centralized heating network project spanning from Yangcheng Power Plant to Jincheng, once operational, will establish a complementary operation pattern with the Jincheng Thermal Power Plant, forming two major heat sources for the east and west. The total heating capacity of the urban area reaches more than 50 million square meters. The heating range can cover the main urban area, Danhe New City, Nancun area, Beishidian area, and villages and towns along the pipeline. The centralized heating capacity and safety have been greatly improved.

The heat input from Yangcheng Power Plant can replace existing coal-fired heating boilers in urban areas, saving 480,000 tons of standard coal per year, reducing emissions of 32,000 tons of sulfur dioxide, 1.04 million tons of carbon dioxide, 14,000 tons of soot, and 315,000 tons of ash.